Barnetts Lock Bridge is a two span steel structure which carries the BHL line over a fastflowing section of the River Kennett. Being located in the heart of a SSSI (Site of Special Scientific Interest) in the beautiful Berkshire countryside, made this site a special place to work. Permission was granted by the Environment Agency to carry out the needed works to replace the life expired bridge bearings. Stobart Rail installed their own floating pontoon system as a working platform which prevented damage to the river bed & protected the habitat of the many aquatic species abundant in this river.

A cantilever jacking arrangement was installed to support the beam ends to enable the replacement of the bearings to the piers. Steel needles were inserted into the abutments which acted as a platform to jack up the other ends of the main girders. The old bearings were cut out by core drilling a series of holes beneath the bearing into the bedstones on the piers and abutments. New bearings were installed and clamped to the bottom flanges of the girders. A timber formwork face and dam was installed around the new bearing plates and high strength grout poured into the void to secure and support the new bearings.

Upon completion of the works the floating platform was removed and the area was left in the same condition as before the work started.

Drive On Hull Support Module

Drive On Hull Support Module Double Float Module

Double Float Module Single Float Module

Single Float Module Single Module Float (Half Depth)

Single Module Float (Half Depth) Sliding Nut

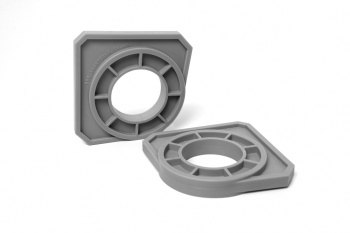

Sliding Nut Spacer Disc

Spacer Disc Standard Nut

Standard Nut External Connecting Pin

External Connecting Pin Internal Connecting Pin

Internal Connecting Pin Internal Connecting Pin – Double Length

Internal Connecting Pin – Double Length Mooring Cleat

Mooring Cleat Hand Rail

Hand Rail Kick Plate

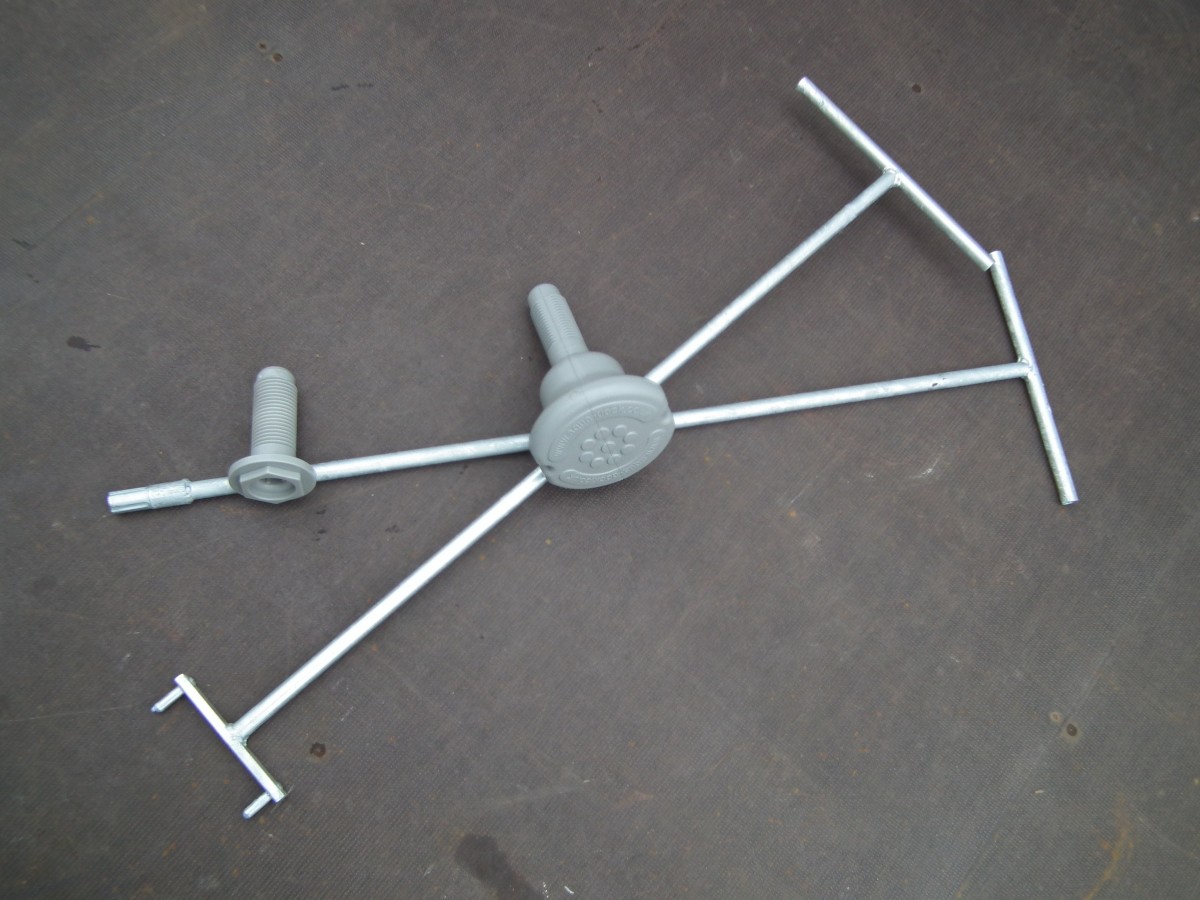

Kick Plate Assembly Tools

Assembly Tools Moulded fenders

Moulded fenders Mooring Ring

Mooring Ring Dock Cushion

Dock Cushion English

English Français

Français Deutsch

Deutsch I wanted to express my gratitude to Aqua-Dock, and in particular Jamie Hooper, for all the assistance provided to me in the acquisition of an Aqua-Dock. Several years ago, I purchased a 7.8m RIB which was kept either on a trailer or in the water. This meant that using the boat either entailed lengthy launch and recovery or regular, in-water cleaning of the hull. This last summer, I bit the bullet and purchased an 8.2m RIB but decided to look into alternative ways of keeping the boat and started to research drive-on docks. I looked at a few makes but following the recommendation from the boat manufacturer, contacted Jamie at Aqua-Dock. Apart from the very competent and friendly service from Jaimie, what sold me on the dock was the rollers extending the length of the dock which was a system other docks I looked at did not have. Jamie helped design the dock, advising on the best dimensions which, once installed, has allowed me full access to the boat when out of the water.

I wanted to express my gratitude to Aqua-Dock, and in particular Jamie Hooper, for all the assistance provided to me in the acquisition of an Aqua-Dock. Several years ago, I purchased a 7.8m RIB which was kept either on a trailer or in the water. This meant that using the boat either entailed lengthy launch and recovery or regular, in-water cleaning of the hull. This last summer, I bit the bullet and purchased an 8.2m RIB but decided to look into alternative ways of keeping the boat and started to research drive-on docks. I looked at a few makes but following the recommendation from the boat manufacturer, contacted Jamie at Aqua-Dock. Apart from the very competent and friendly service from Jaimie, what sold me on the dock was the rollers extending the length of the dock which was a system other docks I looked at did not have. Jamie helped design the dock, advising on the best dimensions which, once installed, has allowed me full access to the boat when out of the water. Jamie installed our Aqua-dock a year ago and at that time we knew that we would be changing the boat sometime this year. His advice was to give him a call when we had the new boat if anything needed changing. So having just collected the new boat, we found that it was slightly longer and heavier and didn’t sit on / launch off the dock as well as the previous one. A call to Jamie and he proposed a couple of changes that were installed this week. New boat now sitting happily on the Aqua-dock and able to launch with ease.

Jamie installed our Aqua-dock a year ago and at that time we knew that we would be changing the boat sometime this year. His advice was to give him a call when we had the new boat if anything needed changing. So having just collected the new boat, we found that it was slightly longer and heavier and didn’t sit on / launch off the dock as well as the previous one. A call to Jamie and he proposed a couple of changes that were installed this week. New boat now sitting happily on the Aqua-dock and able to launch with ease. Jamie at Aqua Dock is a pleasure to deal with. We designed a dock that works well with my stepped hull, something that I had been told was not possible elsewhere. Jamie also designed and produced some custom brackets for H beams that allows the dock to rise and fall in our tidal location effectively. We had an issue with a winch, that was immediately replaced FOC, under warranty. All in all, we’re extremely pleased with Jamie’s Aqua Dock installation.

Jamie at Aqua Dock is a pleasure to deal with. We designed a dock that works well with my stepped hull, something that I had been told was not possible elsewhere. Jamie also designed and produced some custom brackets for H beams that allows the dock to rise and fall in our tidal location effectively. We had an issue with a winch, that was immediately replaced FOC, under warranty. All in all, we’re extremely pleased with Jamie’s Aqua Dock installation.